Cold storage is changing the way supply chains work, offering key benefits that businesses can’t ignore.

One major advantage is that it keeps perishable goods fresh for longer. This is especially important in industries like food and pharmaceuticals, where product quality must be protected at all times.

Cold storage also improves inventory management. Businesses can store a wider range of products without worrying about spoilage. This means they can respond to consumers’ demands more easily, which boosts customer satisfaction. With more people choosing fresh and organic items, having reliable cold storage gives companies an edge.

Discover how cold storage enhances supply chain efficiency. Learn the top benefits, proper temperature control, and planning strategies every supply chain manager should know.

What is Cold Storage?

Cold storage refers to the practice of storing goods at low temperatures to preserve their quality and extend their shelf life. This method is commonly used in various industries, particularly in food and pharmaceuticals, where temperature control is crucial for maintaining freshness and preventing spoilage.

Cold storage facilities are equipped with specialized refrigeration systems that can maintain specific temperature ranges, ensuring that perishable items such as fruits, vegetables, dairy products, and medications remain safe for consumption or use.

The Benefits of Cold Storage

Speaking from different industries’ perspectives, it’s a challenge to deliver and supply products effectively to meet growing consumer demands. As consumer preferences evolve and demand increases, particularly for perishable goods, supply chain managers have had to adapt. To ensure quality and freshness, they’ve expanded their roles by prioritizing secure storage for temperature-sensitive items, maximizing the benefits of cold storage. Recognizing the importance of this, businesses and supply chain managers are turning to the solution of building more cold storage facilities.

Cold storage warehouses have become essential for both businesses and consumers, offering temperature control to keep goods fresh. These facilities act as crucial intermediaries, preserving perishable items before they are distributed or shipped to distant markets.

Cold Storage in Logistics

Cold storage is a logistics solution that uses refrigeration to keep temperature-sensitive products in good condition. Its main purpose is to store items that need to stay cool or frozen to retain their quality based on their purpose.

Many sectors depend on cold storage facilities to protect the integrity and safety of their products. It is widely used in the food and beverage industry, as well as in the chemical and pharmaceutical sectors.

Aside from keeping perishable goods fresh and stable, cold storage facilities offer several other benefits:

Five (5) Main Benefits of Cold Storage

1. Prolonging the Shelf-Life of Perishable Goods

Cold storage is a logistics facility where perishable goods are stored at lower temperatures than average, and is done in several ways. The controlled atmosphere storage or refrigerated warehouse regulates various gases through precision devices and instruments to keep raw products as fresh as possible. Reducing room temperature or lowering oxygen levels helps the respiration of goods and increases their carbon dioxide supply.

2. Temperature Control

There is no such thing as “one-temperature-fits-all”, especially when it comes to sustaining and ensuring the safety of perishable products. Some industries use a temperature standard that will accommodate the majority of their products. The most common temperature standards are:

DEEP FREEZE

-25 to -30 °C: This can be maintained by conventional refrigerated units that are mostly used for transporting seafood and ice cream.

FROZEN

-10 to -20 °C: This temperature range falls into the range of uses for transporting different kinds of frozen meat and frozen bakery products, such as cakes and bread.

CHILL

2 to 4 °C: It is commonly used to transport fruits, vegetables, and fresh meats as it bestows optimal shelf life without freeze damage.

PHARMACEUTICAL

2 to 8 °C:This range comprises most of the pharmaceutical goods, such as vaccines, that are being transported and are mostly transported in smaller refrigerated packages.

PERISHABLE GOODS

0 to 5 °C: Mostly utilized by tropical fruits such as bananas, oranges, and pineapple, as do tubers, such as potatoes, in the vegetable sector.

3. Cost-Efficiency

Many businesses focus on keeping their products safe, high-quality, and long-lasting. Because of this, their primary concern is how it will become cost-effective. As cold storage prevents deterioration, it might lessen the company’s loss, resources, and energy wasted by clients. For instance, the recent development in cold storage technology—gas-controlled storage—keeps the room pressure as low as 0.8 °C, which saves a lot of energy, and saving a lot of energy will lessen the client’s expenses.

4. Carefree Transportation

Industries that need their products, such as frozen foodstuffs, poultry, dairy products, and even pharmaceutical products, to be transported from their storage facility cannot be distributed at ordinary temperatures. A sudden and slight temperature change can cause contamination and unmarketable goods. It is a huge advantage for them to have a portable cold storage unit, as it is used to keep and transport their products safely at low temperatures. It can also be used to transport highly reactive chemicals that would be impossible to transport.

5. Saves Space

Space utilization becomes a pressing matter for businesses with too many products to store, and it becomes an even bigger issue for those with temperature-sensitive goods. In this case, you have another space to conveniently store your excess and raw products, which will be easy to find whenever you need them. You will not just keep your place organized, but you will also reduce waste and store your products category-wise.

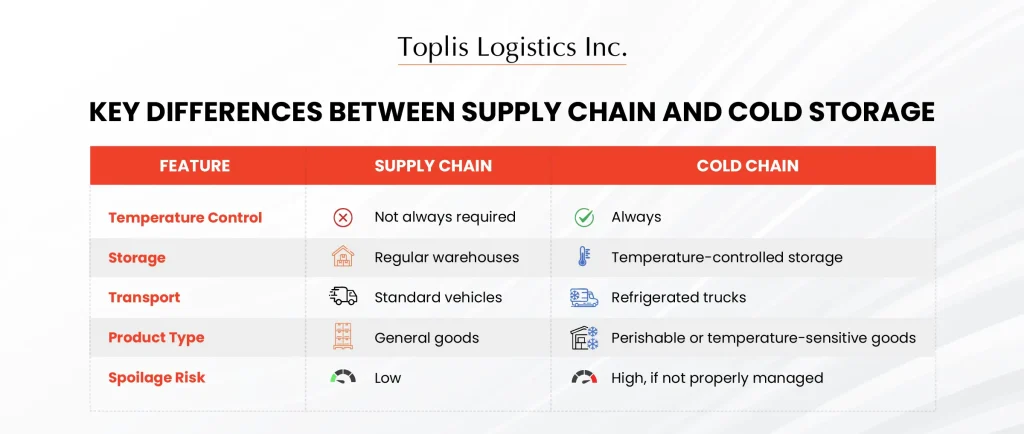

The Difference Between Cold Chain and Supply Chain

More businesses are now investing in cold chain infrastructure. This is because of the growing demand for fresh food and strict compliance with goods and medicines in transit and storage. Cold chain systems help keep products at the right temperature during transport and storage. As consumers choose healthier and better-quality products, companies see cold chain solutions as a way to stay competitive and keep their customers happy.

A standard supply chain doesn’t always need strict temperature control. But a cold chain must keep products cold or frozen from storage to delivery. This means using special tools like refrigerated trucks or reefer vans and temperature-controlled warehouses to keep products from spoiling.

Challenges and Solutions in Cold Storage and Supply Chain

High Energy Costs

High energy costs are a significant concern for businesses involved in cold storage. These operations often require precise temperature control to ensure the safety and quality of perishable goods or finished products. The refrigeration systems used in cold storage facilities are typically among the largest consumers of electricity, leading to increased operational expenses.

To mitigate these high energy costs, companies can invest in energy-efficient refrigeration equipment. However, it will require regular maintenance of cooling systems. This will help enhance and expand the lifespan of the equipment. The process involved in equipment maintenance includes routine checks on insulation, refrigerant levels, and overall system performance.

Lack of Facilities in Remote Regions

Many developing areas struggle with access to cold storage facilities as they face unstable electricity supply, poor modes of transportation, and insufficient investment in refrigeration units. These regions often lack the necessary facilities and equipment to maintain temperature-controlled environments, which are commonly experienced by medium-scale farmers in the agriculture industry.

To address this challenge, a multiple approach is needed, mainly focusing on green technology utilization and close cooperation of the people involved. This includes deploying solar-powered cold storage units and establishing a partnership between the local government and public sectors, together with local communities.

Inconsistent Temperature Monitoring

Inconsistent temperature control in cold storage and the supply chain can lead to product spoilage, reduced shelf life, and the growth of harmful bacteria, all of which can pose serious health risks to consumers. These issues often result in increased waste and higher operational costs. Ultimately, poor temperature management affects product quality, leading to customer complaints and damaged brand reputation, which can disrupt business operations and erode trust in the supply chain.

To prevent this, conduct scheduled maintenance activities to easily identify defective equipment. Use continuous temperature monitoring systems, and keep airflow and insulation in the cold storage facility to ensure they are working properly. Regularly inspect refrigeration units and fix any issues right away to avoid breakdowns that can potentially hamper operations.

Cold Storage Planning Tips for Supply Chain Managers

Supply chain managers ensure that the cold storage facility provides premium customer service and implement meticulous yet effective improvements to move beyond traditional supply chain techniques.

Choose the Right Facility

When it comes to cold storage, selecting the right cold storage facility for sourcing raw materials is a competitive advantage. A well-suited cold storage facility should not only meet your temperature requirements but also be strategically accessible to minimize transportation costs and reduce lead time.

Effectively Manage Logistics and Last-mile Delivery

Make sure that your logistics provider is equipped with temperature-controlled vehicles and has a robust tracking system in place, just like what Toplis Logistics can provide. This ensures that your products will remain at optimal temperatures throughout the supply chain, reducing spoilage and maintaining quality.

Ensure End-to-End Temperature Control

Ensuring end-to-end temperature control is essential for preserving the integrity of perishable goods. Implementing advanced monitoring systems can help maintain consistent temperatures from the warehouse to drop points. Regular audits and staff training on best practices in handling cold storage can further enhance compliance with safety standards, ultimately leading to a more efficient supply chain operation.

By focusing on these key areas, supply chain managers can optimize their cold storage strategies for better performance and reliability.

Conclusion

Cold storage helps keep temperature-sensitive products in the right condition throughout their journey. Meanwhile, a supply chain covers the full journey of a product—from production to the customer.

While cold storage is essential, it also comes with challenges. These include keeping temperatures stable, managing energy costs, and following safety rules. Supply chain managers must stay ahead of these issues to protect the finished product or service quality and reduce losses.

To make cold storage work well, planning is key. Businesses should focus on the right location for storage, use specialized tools and equipment to monitor temperatures, and train staff to handle perishable items properly.

By understanding the cold chain and planning carefully, supply chain managers can significantly improve efficiency and protect their products before releasing them to the market for immediate consumption.

In Search of a Cold Storage Facility for Your Business?

Pick the perfect one; Choose Toplis Logistics for your business! We provide facilities to keep your products safe. We also offer a cold storage room, no matter what size you need!

Contact Us