How Having a Proactive Partner Can Improve Your Logistics Operations

Efficient logistics operations help businesses deliver products on time and keep customers satisfied. From warehouse management to transportation, every step matters. Because when logistics processes are slow or unorganized, delays and extra costs quickly follow.

In this guide, we share practical and easy-to-apply tips to help you optimize your logistics operations and improve overall efficiency.

Table of Contents

Improving Operational Efficiency in Logistics

- What is Logistics Operations Management?

- Why Proactive Logistics Partner Matters for Business Success

Tips to Help You Improve Your Logistics Operations

- Tip#1: Enhance Your Warehouse Layout and Workflow

- Tip#2: Use the Right Logistics Technology

- Tip#3: Have a Proactive Logistics Partner

- Tip#4: Improve Inventory Accuracy and Forecasting

- Tip#5: Ensure Seamless Transportation and Delivery Systems

- Tip#6: Train and Upskill Your Logistics Team

- Tip#7: Monitor KPIs to Drive Continuous Improvement

Improving Operational Efficiency in Logistics

What is Logistics Operations Management?

Logistics operations cover the movement, storage (depending on the product classification, it could be in the form of cold storage or dry storage), and handling of goods from origin to destination. When managed properly, they reduce costs, prevent delays, and support business growth.

Logistics operations typically include:

- Inventory management

- Warehouse operations

- Transportation and delivery

- Order fulfillment

The main goal is simple: move goods efficiently, safely, and on time while keeping costs under control.

Why Proactive Logistics Partner Matters for Business Success

A proactive logistics partner does more than move goods. They help identify problems early and offer solutions before delays happen.

Working with the right partner can help you:

- Reduce operational costs

- Improve delivery performance

- Increase customer satisfaction

- Avoid disruptions during peak seasons

A strong logistics partner becomes an extension of your business, not just a service provider.

Tips to Help You Improve Your Logistics Operations

Tip#1: Improve Your Warehouse Layout

A well-organized warehouse supports faster picking and fewer errors.

What you can do:

- Arrange items based on demand and frequency of use

- Clearly label storage areas and aisles

- Remove unnecessary obstacles

Why it matters:

An optimized layout reduces handling time and improves order accuracy.

Tip#2: Use the Right Technology in Logistics Management

Using the right technology helps you solve logistics problems before they get worse. Some useful tools include:

- Warehouse Management System (WMS)

- Transportation Management System (TMS)

- Real-time tracking platforms

These systems let you track stored goods and improve team communication. They also help you make better decisions using real-time data and ensure smoother operations.

Tip#3: Have a Proactive Logistics Partner

Outsourcing logistics tasks allows your business to focus on core operations.

Look for a logistics partner that offers value-added services that include:

- Skilled and trained manpower

- Process optimization support

- Technology-driven solutions

A proactive partner helps you respond quickly to changes in demand and operational challenges.

8 Signs Your Distribution Operations Need a Logistics Partner

Discover 8 warning signs your distribution operations could benefit from a reliable logistics partner like Toplis Logistics.

Tip#4: Improve Inventory Accuracy and Forecasting

Poor inventory control leads to stock shortages and delivery delays.

To improve accuracy:

- Conduct regular inventory checks

- Use forecasting tools to predict demand

- Track stock movement in real time

Accurate inventory data ensures smoother operations in the supply chain and sustain better customer service.

Tip#5: Ensure Seamless Transportation and Delivery Systems

Transportation issues often cause the biggest delays in logistics.

Improve transportation by:

- Using route optimization tools

- Monitoring deliveries with GPS tracking

- Measuring performance through KPIs

Track metrics such as delivery time, cost per trip, and delivery success rate to identify areas for improvement. Free apps like Google Maps and Waze can improve your logistics process and increase profitability.

Check out Toplis Logistics in Google Maps and Waze!

Tip#6: Train and Upskill Your Logistics Team

Your workforce plays a critical role in logistics efficiency.

Focus on:

- Safety and compliance training

- Proper use of logistics systems

- Cross-training employees for flexibility

A skilled and adaptable team can handle peak demand and unexpected disruptions more effectively.

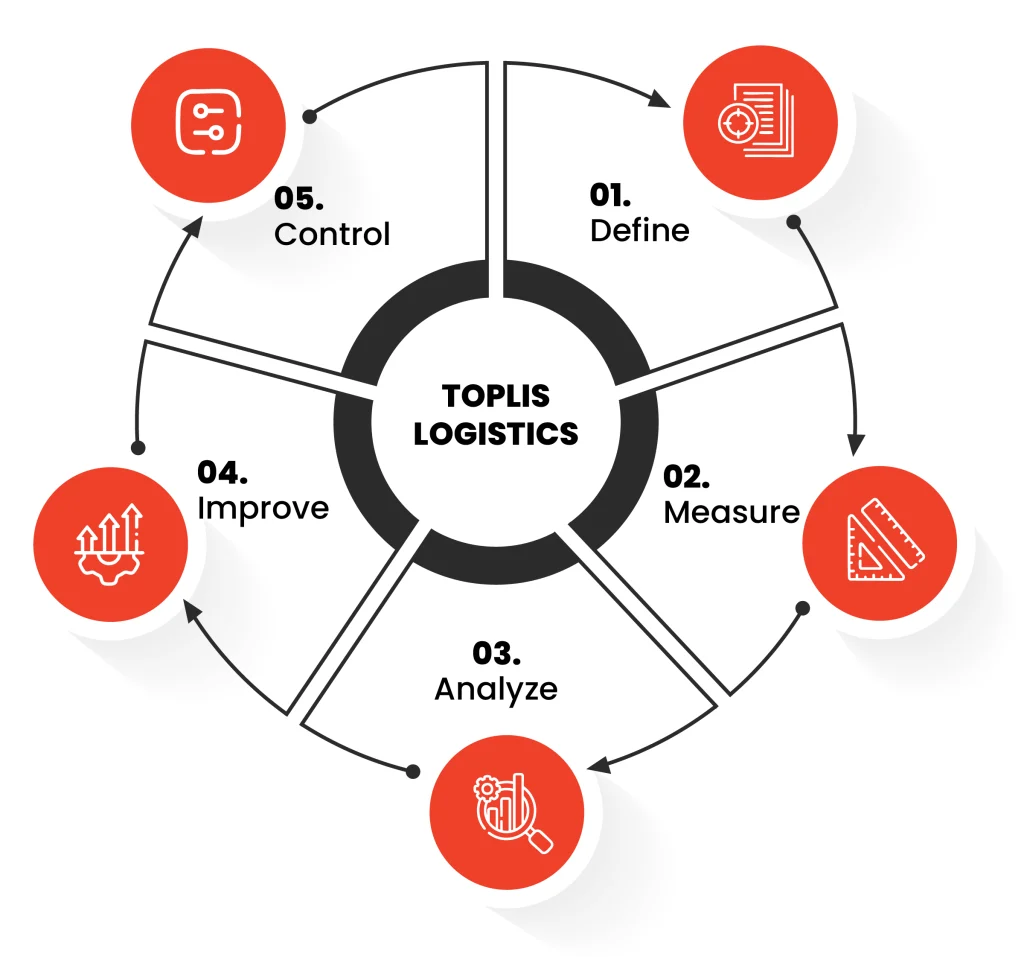

Tip #7: Monitor KPIs to Drive Continuous Improvement

KPIs help measure how well your logistics operations are performing.

Common logistics KPIs include:

- Order accuracy rate

- Warehouse productivity

- Transportation cost efficiency

Regular monitoring helps you make data-driven decisions and improve performance over time.

How a Proactive Partner Can Improve Your Logistics Operations

Working with a proactive logistics partner like Toplis Logistics can improve your entire supply chain. At Toplis Logistics, we offer expert services, skilled manpower, and flexible warehouse solutions that grow with your business.

Whether you’re entering new markets or handling seasonal demand, Toplis Logistics is a trusted 3PL and staffing provider that helps keep your logistics operations smooth and efficient.

Conclusion

Improving logistics operations doesn’t mean you need big changes or rushed decisions. Small, smart steps can make a lasting impact. Focus on key areas like inventory, staffing, transportation, and delivery to streamline your process and stay competitive.

Using the right technology in these areas helps increase accuracy, improve efficiency, and lower costly mistakes. A proactive logistics partner also adds value, especially during peak seasons, capacity changes, or complex distribution challenges..

Frequently Asked Questions

To optimize logistics operations, focus on streamlining workflows, using modern technology, integrating automation, and improving communication across the supply chain.

You can improve logistics operations by optimizing delivery routes, streamlining warehouse tasks, managing inventory better, using real-time tracking tools, and building stronger relationships with suppliers.

Use real-time tracking and route optimization tools, maintain accurate inventory through WMS, and train staff on packing and dispatch protocols to minimize delays and errors.

Hire flexible workers, provide cross-training, use workforce management software, and partner with logistics workforce provider to scale during demand surges.

Adopt automation, optimize warehouse layout, integrate WMS with TMS systems, and use data-driven inventory methods.

The industry faces a high turnover rate, a shortage of skilled labor, seasonal staffing imbalances, and ongoing training and safety compliance issues.

Ready to Strengthen Your Logistics Operations?

Partner with a proactive team that understands your challenges and delivers results tailored to your logistics needs.

PARTNER WITH TOPLIS LOGISTICS